HUF HAUS. The Original. Since 1912.

Thank you for considering HUF HAUS as your partner to build your new dream home.

Be inspired by how exceptionally close to nature your life will be in a HUF house!

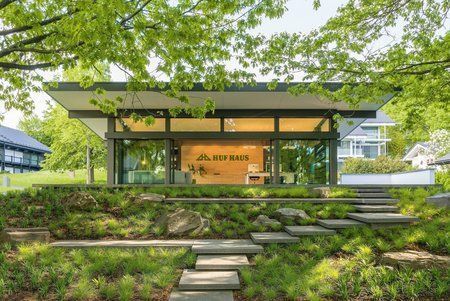

Welcome to HUF HAUS London!

Book your personal consultation appointment to explore the fantastic UK Show House and experience just a taste of the many options HUF HAUS have to offer you.

Extending to 428 sq m, the six bay show house offers generous, open plan living accommodation, including a spacious kitchen fully fitted with fixtures by StilART - part of the HUF family of companies, an expansive sitting room, and a grand dining area located beneath the mezzanine level with roof top windows.

Characterised by the expanses of glass synonymous with HUF HAUS architecture, our show house has unparalleled insulation, airtightness and fabric efficiency, ensuring that the floor to ceiling windows flood the interiors with natural light, contributing to good health and psychological well-being, without compromising on energy efficiency.

YOUR BENEFITS AT A GLANCE

- Family business with over 112 years of experience

- Turnkey design houses made of timber and glass

- Use of premium quality building materials

- Fix price guarantee

- All services from a single supplier with the specialists from the HUF Group

- Experts for sustainable and energy efficient building solutions

- Specialist after-care service

112 Years

HUF HAUS NEWSROOM

Explore project!

Best Architecture Single Residence in Surrey

![[Translate to English - UK:]](/fileadmin/_processed_/b/f/csm_Award_winning_HUF_House_b97968493d.jpg)

HUF HAUS are Winners at the Guildford Design Awards 2021

Additional living space thanks to bespoke loft conversion

Escape the Ordinary with a Stay at a Luxury HUF Holiday Home

First HUF house in Malahide, Ireland

Premium Prefab homes

Seamless and tranquil. HUF HAUS post-and-beam architecture combined with full glazing provides a visual gateway to nature, thus creating a unique daily experience of light and calm.

Floor-to-ceiling glass and fully glazed gables flood your living spaces with light, creating a sense of openness and freedom. Natural daylight undoubtedly contributes to our well-being.

HUF HAUS only build with biologically assured, high quality materials. All components of a house are designed and manufac-tured in the HUF HAUS production facilities in Hartenfels, Germany. Not only does in-house production guarantee that our products adhere to the most stringent sustain-ability standards, it also reduces CO2 emissions through shorter supply demands.

112 years of experience

A company that is successfully operating in the fourth generation and is about to start the fourth can not only be proud of the past but can also promise a good future to employees and customers with confidence. With 111 years of experience, HUF HAUS is today the European market leader for modern post-and-beam architecture.

Anyone who chooses a state of the art prefabricated house from HUF HAUS can be sure that they will be well looked after, even many years after the house is complete. During the warranty period and beyond, the ServiceART team will be happy to answer any questions you may have regarding the upkeep, refurbishment, extension or modernization of your home.

As times change, so do tastes and preferences. You may find that after a number of years you would like a new bathroom or a living room extension. ServiceART is your customer care team ready to assist you with all you post completion needs. As a HUF house owner, you automatically become a member of the HUF Club, which invites owners for periodic events to stay in touch with us and meet other HUF house owners. We look forward to welcoming you into the HUF family!

A new breed of prefab

Once upon a time, a prefab was a basic construction - functional but architecturally uninspiring. Welcome to a new breed of prefab!

The tailor-made HUF HAUS homes are bold and elegant, not to mention highly energy efficient and entirely individual. These exquisite houses incorporate the benefits of prefabrication to enhance their features. The factory construction under ideal controlled conditions ensures the highest standards of quality and assures that the on-site assembly runs smoothly and quickly.

HUF HAUS has embraced the benefits of prefabricated construction and combined them with innovative design and true craftsmanship. The result is a house that boasts of expansive external glazing despite being exceptionally energy efficient. It features a very fast build time but with zero on-site waste. It is noted for its bespoke architecture where every house is individually designed for a specific client and yet it is a prefabricated house, factory built.

The days when prefabricated houses meant uniformity and cheap construction are long gone. On the contrary, more and more builders are discovering the advantages of prefabricated houses.

The plannability, speed and quality are particularly valued: prefabricated houses are - as the name suggests - completely prefabricated in the factory and erected within a few weeks on a prepared cellar or base slab. The individual elements form functional units. This guarantees minimum dimensional tolerances and the absence of dreaded thermal bridges. Prefabricated houses are always also energy-saving houses.

Of course, all this also applies to HUF's "prefabricated houses".

The generous glazing with fine wooden support elements constitutes the first significant difference to conventional prefabricated houses. The triple insulated thermal glazing must thereby have the same thermal performance as a thermally insulated wall. On the one hand, heat must be kept in the house; additionally, the house will not get too hot in bright sunshine.

Each piece of glass is a high-tech product: vapour-plated with a reflective layer and filled with a noble gas that prevents heat transfer, the glazing achieves sensational insulation values - and give the HUF Haus its unmistakable transparent appearance and bright interior spaces.

Premium: Post-and-beam construction

The load-bearing parts are mainly made of timber. Relatively delicate horizontal and vertical wooden beams bear the load and redefine tried and tested principles of timber-frame construction. The durability and longevity of the timbered principle can still be admired in many old towns today. 500-year-old post-and-beam houses are not uncommon - even if the sometimes eccentrically-inclined beams do not serve as the model. Today's glued and joined timber constructions have long since overcome this disadvantage.

What remains is sustainability. As a renewable raw material, wood combines ecology with economy. The vast majority of prefabricated houses today are built from wood, as no other material combines so many positive properties. Nevertheless, there are unmistakable differences to conventional prefabricated houses: Modern HUF timber frame houses are not manufactured according to either the classic timber frame construction method or the solid timber construction method. The slender timber-glass construction forms a latticework resembling a skeleton - the characteristic feature of the so-called skeleton construction method.

Finally, this type of construction ensures individuality. No two HUF houses are the same, since the individual parts of the "skeleton" can be rearranged in almost endless ways, completely as the owner wishes.

Our ultimate conclusion: Discussion of whether an HUF house is a prefabricated house or not is purely academic.

HUF houses combine all the advantages of prefabricated houses with an unmistakable timber-glass look and a modern timbered design.

The overall package ensures that this building style is becoming more and more popular both nationally and internationally, and that is ultimately what matters.

Maximum Quality for prefab houses

Unique Timber Protection Concept

For many decades HUF HAUS have championed The Comprehensive Timber Protection Concept – one of a kind within the industry. Independent testing concludes that HUF HAUS exceeds legal timber protection standards "with innovative detailed solutions and exemplary results", as assessed by timber protection expert and former academic director Borimir Radovic.

Selection of Premium Materials

HUF HAUS work exclusively with Nordic Spruce enabling us to meet our exacting standards in high quality long- lasting construction. Particularly weather-resistant Spruce is dried by controlled methods and subsequently glued in narrow slats. This procedure creates a visually appealing product with tremendous weight bearing capacities and dimensional stability. The large roof overhang is also integral to the HUF HAUS design and provides additional protection against the elements.

Excellent Insulation

Several layers of intricate roof insulation create comfortable living temperatures throughout the Summer and Winter months. The separate raft insulation in the roof prevents corresponding outdoor temperatures from penetrating house and rooms, whilst triple glazing and the unique external wall construction also play a major role. Additional layers of insulation can be added to the inside to adapt the house for varying regional climate conditions.